Behind the Scenes with Senior Designer Diego Arias

Diego Arias, Senior Designer at Pembrooke & Ives, brings a deep appreciation for materiality, detail, and a profound respect for artistry to his role. He holds a Master’s degree in Architecture and has years of experience in product design, having played a key role in developing our collaborative collection with Hudson Valley Lighting. Most recently, Diego led the design of a custom mantel for our 79th Street Duplex project, a striking piece defined by its arched opening and distinctive raked stone finish. We spoke with Diego to learn more about the design journey, from the earliest sketches to final installation, and the craftsmanship behind this sculptural focal point.

What was the initial inspiration behind this mantel design?

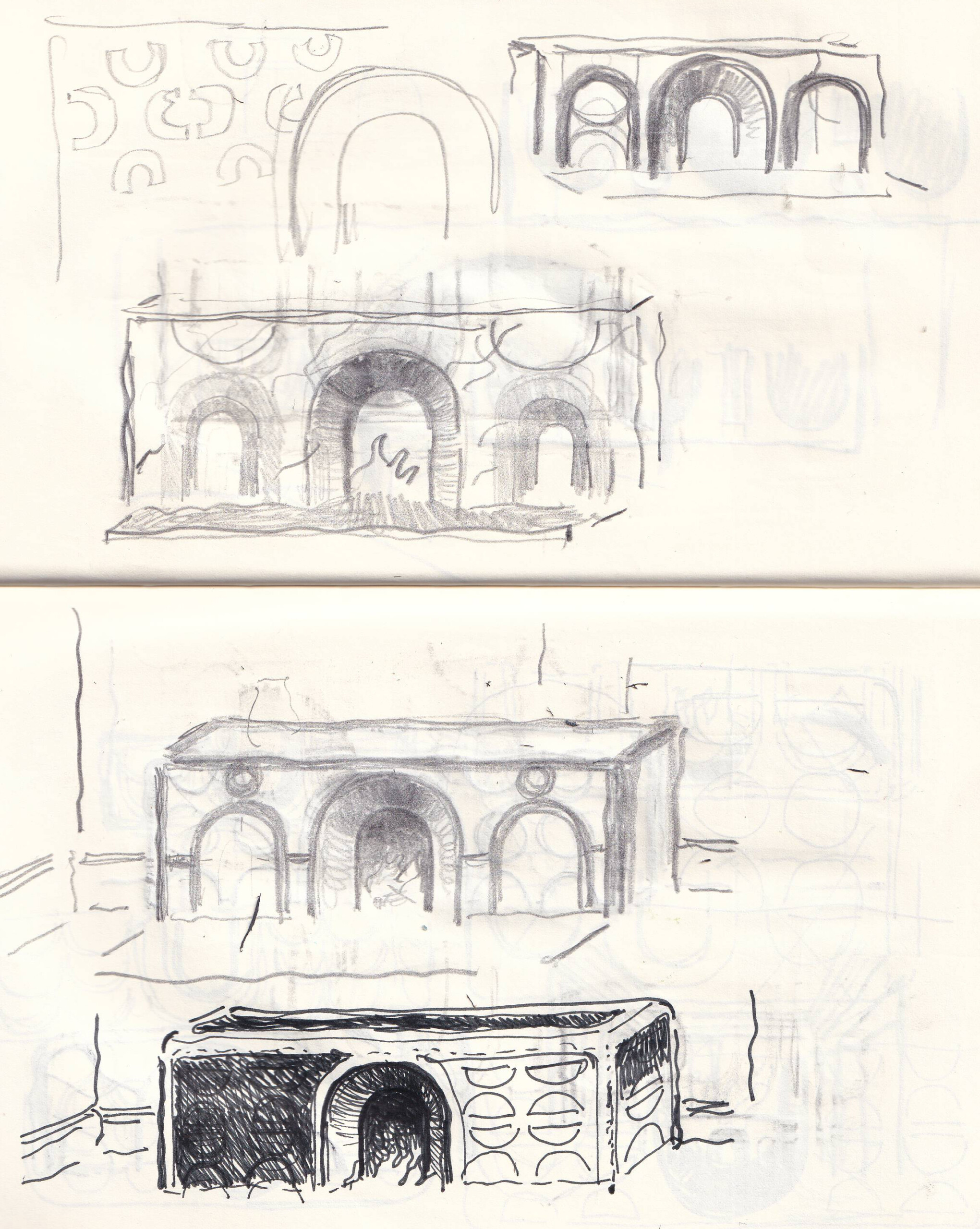

Our client loved soft edges and arched openings, so we started with that premise and developed ideas that celebrate this form.

Was there a particular architectural reference, or material that informed your vision?

The overall reference was just thinking distantly of the west coast where our clients lived. We did not reference something literally.

How did the surrounding interior, like the room’s scale, furnishings, or overall aesthetic, shape your approach?

We made the fireplace slightly horizontal to give the impression it’s enveloping and welcoming, and the arch and curves are slightly reminiscent of California’s missions.

What were the first steps you took once the project began? Were there early sketches or mood boards involved?

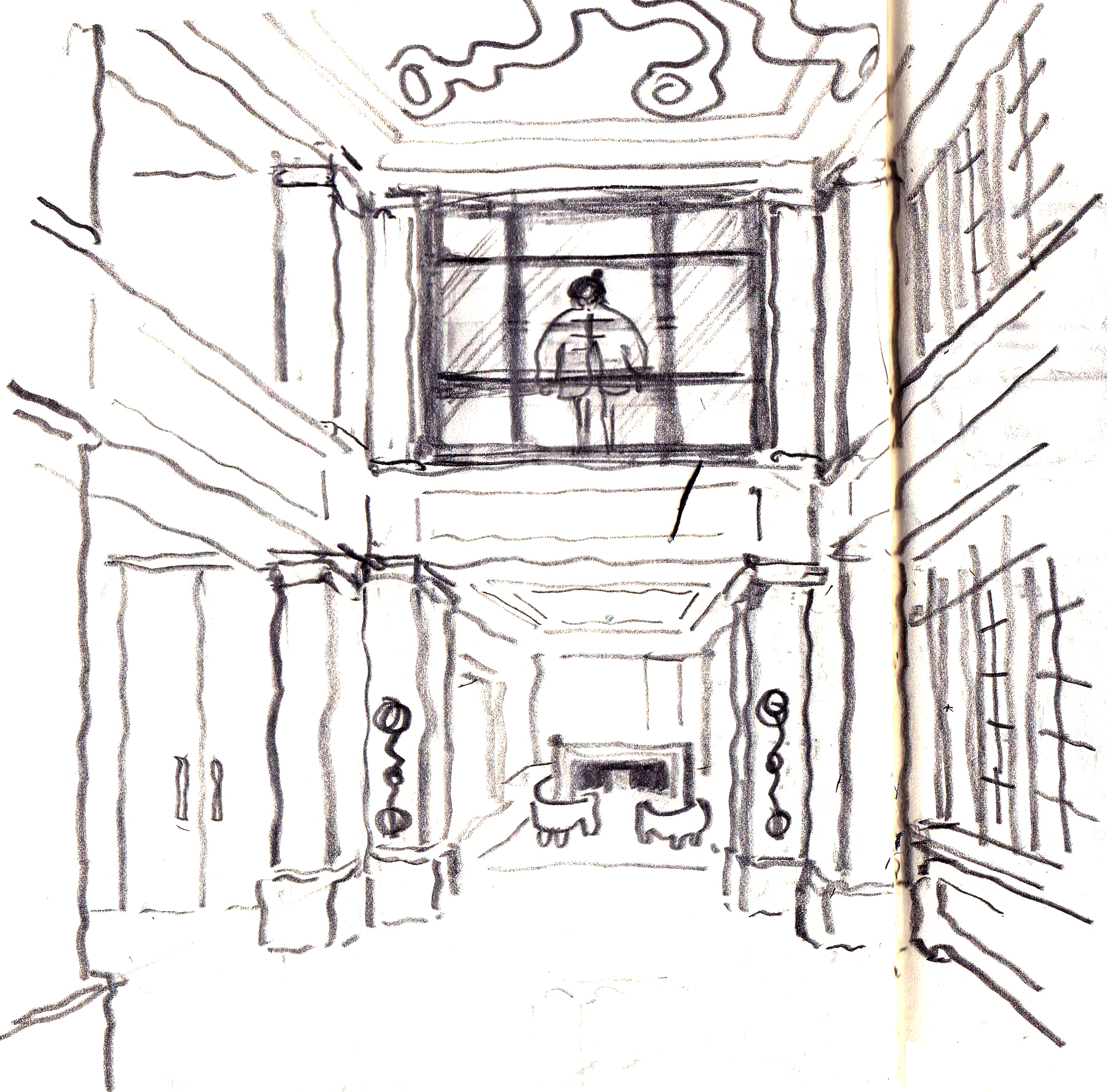

Many sketches and 3D studies!

Had you designed fireplace mantels before, or was this your first time exploring this typology?

Yes, many times! It’s one of my favorite features to design as the mantel is the heart and center of a home. They bring a grounding weight to the space.

How did your ideas evolve throughout the design process, and were there any pivotal moments that shifted the direction?

The ideas evolved working closely alongside the client to develop the design. She had a strong vision and input in selecting the mantel material. We first came up with a shape, and then worked with the materiality to further refine the form prior to fabrication.

How did you approach material selection for the mantel? Were there specific performance or aesthetic qualities you were looking for?

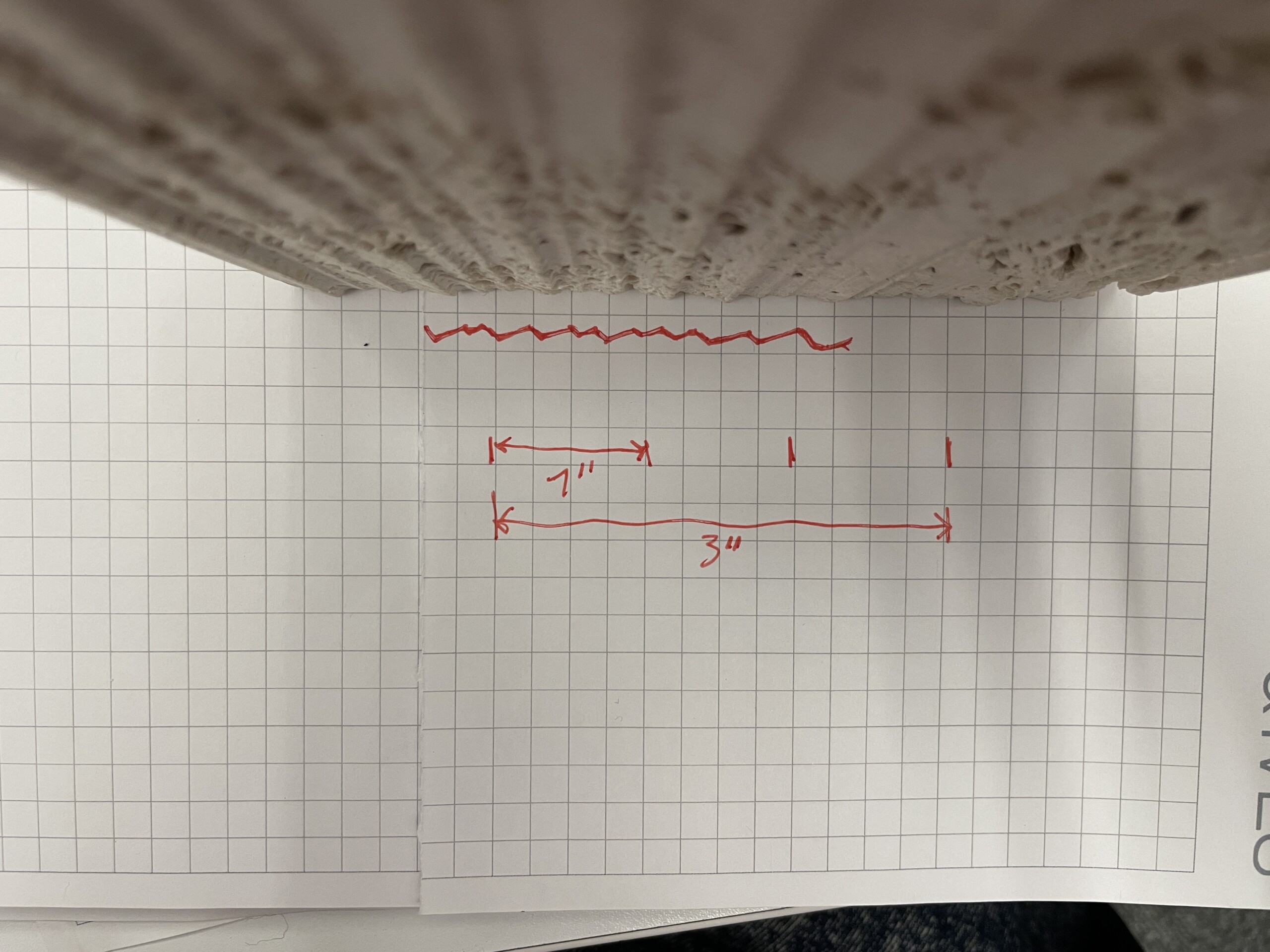

We knew the mantel material for the fireplace had to be special. We also knew we wanted to have an arched fireplace opening as a single three-dimensional piece that could be cast, a beveled-arch. This is how we decided to create the arch in terrazzo and the fireplace mantel in a more decorative finish, un-filled travertine, which reminded the client of coral reefs and her birthplace, Puerto Rico.

We worked over a long period of time with our terrazzo vendor to produce a custom terrazzo that matched the hue and tone of the unfilled travertine. We succeeded in marrying contrasting but complimentary materials.

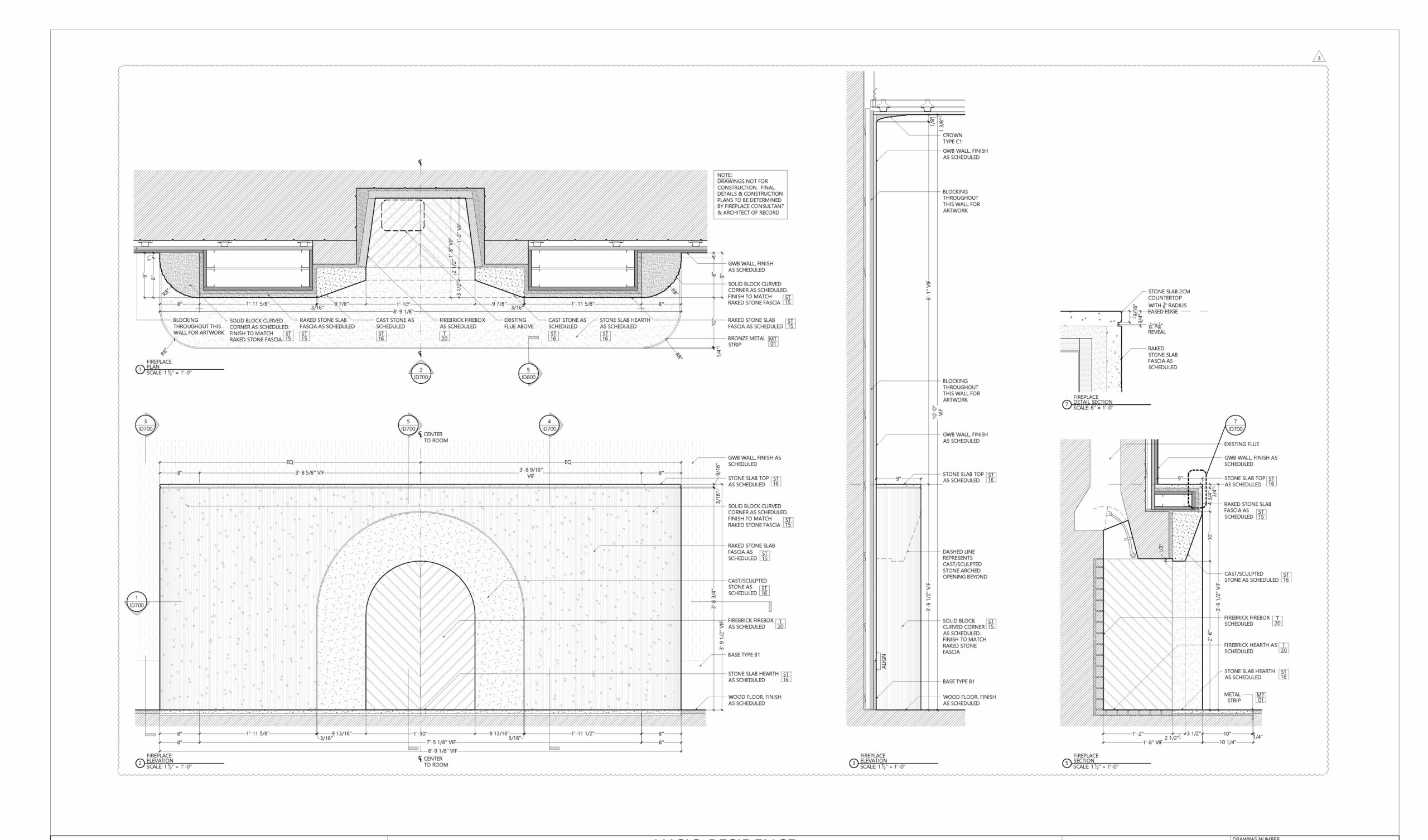

What technical considerations do you have to keep in mind when designing a custom mantel, such as weight, installation methods, or fire safety?

The travertine was fabricated with a raked texture that allowed us to conceal the facets of the curved corners. The fireplace gives the impression of a solid 9” thick solid block, but it is actually made from ¾” slab pieces. So there are ways you can trick the eye with fabrication techniques.

Did you consult with artisans or fabricators during the design phase to better understand what was possible or advisable?

We consulted frequently with our terrazzo vendor and our stone fabricator. They were very talented and helpful along the way.

Is there a general rule or guideline you follow when determining the mantel’s height, depth, and overall scale?

Yes, many. Some practical, some aesthetic. What sits above the fireplace? What is the existing fireplace opening size? What is the scale of the room?

How detailed are your drawings and elevations when preparing a custom piece like this, what types of specifications do you typically include?

Our drawings were very detailed, and we had a complete drawing sheet dedicated to the fireplace in our construction set. We included the material selections, the bronze inlay around the hearth, the profile/shape of the raking, and additional notes that highlighted the particularities of the design.

How do you help clients visualize and connect with a piece that doesn’t exist yet, especially something architectural like a mantel?

There was plenty of 3D modeling done for the project. 3D modeling and sketching is a necessary tool for designers and clients. It helps the designers design holistically and leaves no stone unturned in terms of resolving every aesthetic connection and angle. It also helps clients visualize the product they will receive and have a constructive input in the process. Without 3D visualization or drawing, it’s hard to create bespoke pieces.

Once the design was finalized, what did the fabrication timeline look like? Were there any unexpected challenges?

Yes, many! It was essentially constructed by two fabricators, our terrazzo vendor and our stone vendor, with different timelines and priorities. The overall fabrication must have taken around 3-4 months.

What’s your favorite detail or aspect of the finished mantel?

I love how the terrazzo speaks to the travertine! It’s all about the small dichotomies. One is smooth, the other rough, one is man-made, the other natural. Yet they get along very well.